Recycled fibre nonwovens project at Pureko

Dedicated service for Asia from Wuxi.

1st July 2021

Innovation in Textiles

|

Wuxi, China

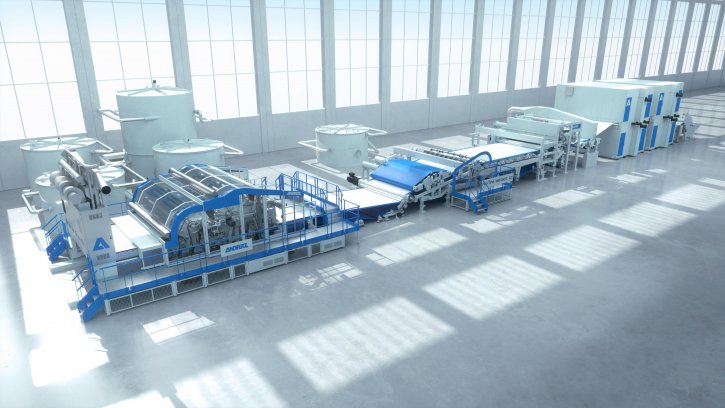

Andritz will present its broad product portfolio for nonwovens and textiles at ANEX/SINCE 2021 in Shanghai, China, from July 22-24.

This encompasses air-through bonding, needlepunch, spunlace, spunbond, wetlaid/Wetlace, converting, textile finishing, airlay, recycling, and bast fibre processing.

The Andritz (China) Wuxi Branch has an experienced platform for production and service specially geared to the Asian nonwovens industry. It designs and manufactures lines for the Andritz aXcess product range, which includes complete lines and individual machines for the air-through bonding, needlepunch and spunlace processes.

The service organisation provides prompt delivery and customer support and a team of technicians and process experts can be deployed quickly on demand to customer sites requiring full-range assistance. The Andritz facilities include a roll service centre with grinding equipment and a test stand for various different roll types.

Among the largest end-use markets for nonwoven products are materials for durable uses. Interior linings for cars, materials for construction, geotextiles, synthetic leathers for clothing and furniture, carpeting, filtration and many other industries rely on nonwovens produced using the needlepunch method.

Andritz needlepunch technology provides customers with a full range of solutions. For needlepunch materials, the Andritz ProWin web control system optimises web distribution, uniformity, profile, and structure via a smart combination of weight profiling control technologies – ProDynT and ProWid.

The company’s processes are also playing a pioneering role in the production of biodegradable materials aimed at the limination of plastic components through blends of fibres such as wood pulp, short-cut cellulosic fibers, viscose, cotton, hemp, bamboo or linen.

The latest development in this field is the Andritz neXline wetlace CP line. This process combines the benefits of two forming technologies –inline drylaid and wetlaid web forming process – with bonding by hydroentanglement. Natural fibres, like pulp or viscose, can be processed smoothly and generate a high-performance and cost-efficient wipe that is fully biodegradable and plastic-free.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more