New offshore blade for Envision in China

The rotor blade design features hybrid CFRP-GFRP spar caps to keep the use of costly carbon fibre to a minimum

1st June 2020

Innovation in Textiles

|

Germany

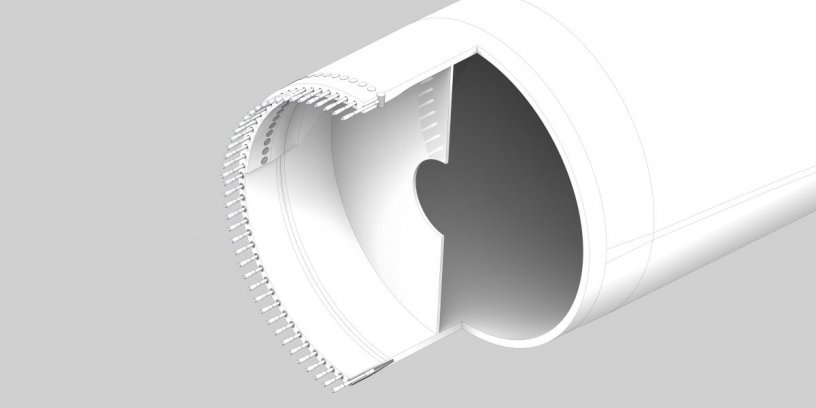

Germany’s aerodyn Energiesysteme GmbH has developed a pre-design for a 111-metre-long rotor blade for an upcoming 11-15-megawatt wind turbine generation. A modern structural concept, combined with aerodyn’s 30+ years of experience in turbine and blade development, lead to a promising pre-design initially optimized for 14 megawatt rated power on a TC1B site. However, to meet the optimum for specific turbine or site conditions the blade design can be widely adjusted, the company reports.

The rotor blade design features hybrid CFRP-GFRP spar caps to keep the use of costly carbon fibre to a minimum. Much emphasis was given to using proven state-of-the-art blade materials and manufacturing technologies.

aerodyn is currently working on 10MW offshore wind turbines, and the components will go into production in the coming year. The next, even larger generation of systems with around 15 MW wait in the wings, which will probably come to market in the middle of this decade. The big challenge is the current supply chain and the necessary infrastructure for the construction of these giants, aerodyn says.

In addition to rotor blade and complete wind turbine development, aerodyn also offers engineering services, service and consulting for decades.

New offshore projects in deep water require more detailed evaluations, the company explains. It can be assumed that the floating wind turbine market will expand in the coming years, aerodyn adds.

The company has implemented new software and processes and created its own software and is able to offer comprehensive offshore aero-hydro-elastic simulations of the overall system with wind turbines, floaters and mooring. “We are proving the aeroelastic stability of the rotor blade - as an innovative company aerodyn is well prepared,” says aerodyn.

“On floating structures, the turbine is exposed to increased movement and hydrodynamic forces. Currents, waves, anchor loads and misalignment in combination with wind forces influence the overall dynamics and often result in high acceleration forces on the tower head with impact on the drivetrain,” the company explains.

“aerodyn has had experience in the field of floating wind turbines over the years. We have conducted studies with different kinds of floating structures. In order to be able to comprehensively analyse the entire system, we also developed our processes further and improved our software tools. Today we perform sophisticated simulations of our floating wind turbines with HAWC2. We have developed sophisticated pre- and post-processing software aeroHalo which is available which is available for licensing. On request, we also offer this service to the clients, tailored according the specific ideas,” the company concludes.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more