Perfection for compact yarns

Sensors fuse their outputs into a single signal before classification.

7th August 2023

Innovation in Textiles

|

Wetzikon, Switzerland

The simultaneous dual measurement carried out with the Prisma sensor system developed by Switzerland’s Lopefe is the most effective way for spinning mills to detect basic faults in yarn quality while reducing waste, splice cycles and energy consumption.

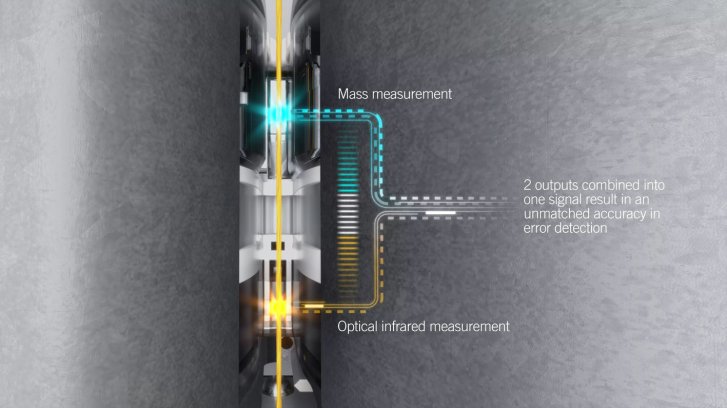

Prisma’s optical infrared and mass sensors work in harmony, combining the two outputs into one signal to guarantee accurate fault detection and the most precise cut execution.

The sensor takes into account factors like raw material type, type of fault, length of fault and even hairiness, which results in the best recognition and classification of faults by length and intensity.

Every sensor technology possesses its strengths and limitations and even with an incorporated yarn clearing system, there may still be defects in the yarn that could result in potential complaints. Through the utilisation of yarn clearers equipped with both optical and capacitive measurements, spinning mills are investing in comprehensive quality control. Significant variations exist, however, among the dual measurement technologies available today.

With the Primsa, both sensors monitor the yarn concurrently, fusing their outputs into a single signal before classifying the detected fault according to its length and strength. The clearing system exclusively assesses this combined output rather than individual signals, guaranteeing the identification of every type of defect regardless of volume, mass or size.

Prisma also offers the neps and short, long or thin fibres (NSLT) cluster feature that can detect irregular accumulations and periodical faults. Operators can easily track the length and combined intensity of each defect in the provided cut history for every spindle, which eliminates the need for separate reporting.

The user doesn’t need to be concerned with configuring or combining the two sensors, or choosing which sensor should take precedence in evaluating and determining whether a fault needs cutting or not. The smart functionality of the Prisma clearer system guarantees an optimal setup is always achieved.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more