Itema strengthens presence in Turkey

iSAVER offers real added value for Bangladeshi weavers dealing every day with Western brands.

13th February 2023

Innovation in Textiles

|

Dhaka, Bangladesh

Itema is exhibiting its R9500-2denim rapier weaving machine at DTG 2023 exhibition in Dhaka, Bangladesh, from February 15-18.

The machine is one of 99 that are being installed at the plant of Universal Denims – one of the largest multi-storey integrated textile operations in Bangladesh, with an annual production of 36 million yards of denim for leading fashion brands and retailers worldwide.

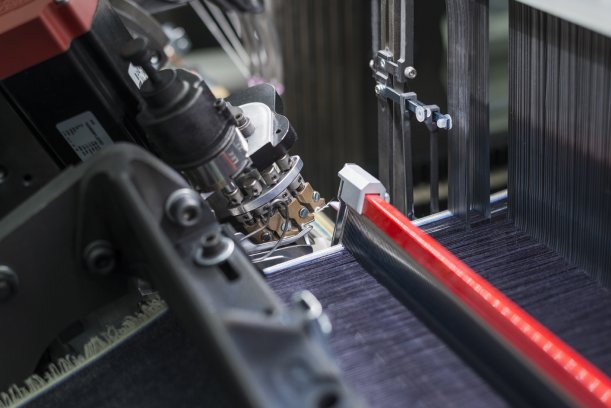

The R9500-2denim on show is equipped with iSAVER, the mechatronic device capable of eliminating the waste selvedge on the left-hand side of the fabric during weaving, leading to significant costs savings and reduced waste. It is already successfully installed in many leading denim mills worldwide and represents real added value for Bangladeshi weavers dealing every day with Western brands, who are increasingly looking for sustainable production chains for the fabrics they purchase.

Itema provides the advanced weaving machines along with a real-time after-sales service, highly professional training for weavers and integrated textile consultancy. It is uniquely positioned in the market to offer the top three weft insertion technologies – rapier, airjet and projectile – as well as OEM spare parts, upgrade kits, and a dedicated online shop for the historic brands which are now part of Itema – Somet, Sulzer and Vamatex – in addition to highly professional training at six worldwide locations.

“Universal Denims works on sustainable manufacturing processes, carbon-footprint reduction,and utility efficiency,” says the company’s MD Atiqul Alam Chowdhury. “The yarns and chemicals used in our plants come from organic sustainable sources, we adopt an ozone finishing process that reduces environmental impact, and fabric stretching is realised with an aero finish to increase durability.

“In addition, our state-of-the-art effluent treatment plant saves 172 million litres of natural water annually and is equipped with e-labs that make our factory extremely eco-friendly. Itema’s technology further helps us in reducing the footprint of our activities, while not having to compromise in terms of weaving efficiency and fabric quality. We are therefore delighted to further enhance our partnership by having one of our Itema R9500-2denim rapier weaving machines on display at DTG.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more