-300x192-cropped.jpg)

Grants awarded for innovation in US textile manufacturing

3D weaving machines will be used to make workwear-style pants under a house brand.

15th March 2024

Innovation in Textiles

|

Oakland, CA, USA

Walmart has announced a pilot project with unspun, the Oakland, California-based developer of Vega 3D weaving technology, which could help reduce the environmental impact of garment production

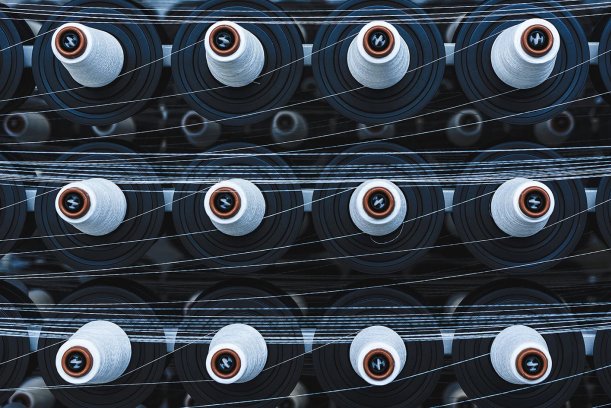

The microfactory of unspun promises to more quickly and efficiently transform yarn directly into garments.

The pilot project aims to addresses concerns about the waste in the apparel industry driven primarily by fabric loss from traditional flat weaving, cutting and garment assembly, and from discarded extra inventory built to meet growing consumer demand and fashion trends.

These issues, combined with the emissions generated from transporting garments and fabrics supplied offshore, have created demand for more sustainable apparel manufacturing supply chain solutions.

“At Walmart, we are laser-focused on bringing innovation to our supply chain to better serve our customers and solve industry challenges and unspun has the potential to do just that,” said Andrea Albright, executive vice president of sourcing at Walmart. “The technology we are piloting has the potential to unlock more skilled job creation in the USA, meet consumer demand for locally made garments and deliver on our commitment for greater transparency and sustainability in our apparel supply chain.”

The two companies will explore how unspun’s 3D weaving machines can be used to make workwear-style pants under a Walmart house brand. With 3D weaving, yarn is spun directly into completed garments, whereas traditionally, yarn is woven into one-dimensional fabrics which are then cut and assembled into garments, creating waste and taking significant time and multiple manufacturing steps. The 3D weaving process is different from commonly known 3D printing, which creates a physical object from a digital design by laying down thin layers of liquid or powdered plastic, metal or cement.

The two companies aspire to deepen the collaboration into later phases should the pilot prove successful. Unspun, in collaboration with a manufacturing partner, hopes to ultimately deploy additional microsites around the USA for on- and near-shored manufacturing, with locations to be determined. It has an ambition to have 350 machines in the USA by 2030.

“We have been running low-volume production of commercial products at our first microfactory with proven third-party life cycle assessments to back the impact of this new type of production,” said unspun co-founder Beth Esponnette. “Together with Walmart, we see an enormous opportunity to take our innovations to scale, with the potential to disrupt the garment manufacturing industry, bring jobs to the USA and drastically reduce waste in apparel.”

The collaboration follows a series of tech initiatives announced by Walmart in recent months. At the Consumer Electronics Show (CES) in Las Vegas in January, Walmart showcased tech-powered enhancements, including expanded drone delivery in the Dallas-Fort Worth region, computer vision exit technology at Sam’s Clubs and AI enhancements for customers, members and associates, along with ambitious commitments to clean energy. In July 2023, Walmart further announced a pilot for carbon capture and conversion technology also for the apparel manufacturing supply chain.

In its own operations, Walmart has set a goal to be 50% powered by renewable energy by 2025 and 100% by 2035. More than 5,900 suppliers globally are engaged in Project Gigaton, and as of February 21, suppliers have now reported projects that are expected to exceed the 1 billion metric ton mark, helping Walmart reach its goal six years early.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more