OceanSafe claims Design Prize Switzerland

Biobased auxiliaries for the dyeing and finishing of next-gen polyester.

24th April 2024

Innovation in Textiles

|

Berne, Switzerland

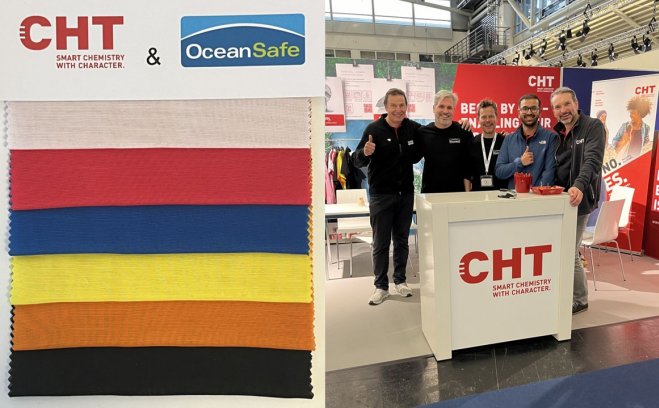

OceanSafe has announced a collaboration with speciality chemicals company CHT to provide solutions for dyeing and finishing textiles made from naNea next-gen biodegradable polyester.

Unlike conventional polyester, OceanSafe’s naNea is biodegradable in the marine environment by over 93% after 99 days and does not contain any toxic substances. At the same time, naNea fibres and yarns match the performance of conventional polyester, making them an ideal choice for products where resilience and durability are paramount. naNea is the world’s first and only synthetic textile material that is Cradle to Cradle Certified at Gold level and is market-ready and scalable today.

Transitioning to naNea in manufacturing processes is easy, in combination with sustainable dyeing and finishing agents, such as those from CHT.

Cooldye is designed for the lower temperature dyeing of all types of polyester fibres – virgin, recycled and biodegradable. Its application to naNea is carried out at 110°C, which is 20°C lower than that of standard polyester, resulting in savings in both energy and time.

The Cooldye system combines Sarabid TS 300, a soy-based levelling agent and Redulit Gin, a sugar-based reducing agent. Both dyeing auxiliaries are biodegradable and meet the highest level of ecological requirements. The Cooldye system is complemented by CHT’s Bemacron HP-LTD disperse dyes that specifically enable the low-temperature dyeing process.

Ecoperl 4, a fluorine-free finishing agent that provides excellent water repellency and very good wash durability, is applied on naNea for achieving a hydrophobic finish effect. It is a biobased and biodegradable product based on special functionalised polymers and waxes.

By utilising CHT’s biobased auxiliaries for the dyeing and finishing of naNea, a compatible and responsible approach is ensured. In addition, the final product made from naNea materials and CHT chemistry can be compliant with the Cradle to Cradle Certification.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more