Monforts to present new Montex XXL stenter at INDEX17

Editor’s Viewpoint

Billy Hunter meets Monforts Vice President, Klaus Heinrichs at ITMA in Barcelona Leading dyeing and finishing machinery manufacturer A. Monforts Textilmaschinen showcased its latest products for dyeing, finishing and sanforising at ITMA 2011 in Barcelona with special emphasis on energy saving solutions and environmental protection. The Mönchengladbach based company showed its wares on an impressive open plan 500 m² booth. Before

17th October 2011

Billy Hunter

|

Barcelona

Billy Hunter meets Monforts Vice President, Klaus Heinrichs at ITMA in Barcelona

Leading dyeing and finishing machinery manufacturer A. Monforts Textilmaschinen showcased its latest products for dyeing, finishing and sanforising at ITMA 2011 in Barcelona with special emphasis on energy saving solutions and environmental protection.

The Mönchengladbach based company showed its wares on an impressive open plan 500 m² booth. Before taking a tour of the booth we talked to Monforts Klaus Heinrichs about the company's focus on energy savings. Mr Heinrichs explained that the company's philosophy in this respect was both clear and simple:

"The ever increasing costs of utilities such as water, gas and electricity plus the rising price of commodities such as cotton are forcing textile producers to seek energy savings in a bid to maintain margins. Against this backdrop, Monforts as a market leader in the manufacturing of dyeing and finishing machines for both knitted and woven fabrics is committed to reducing the energy consumption of its customers."

Mr Heinrichs said Monforts was not only concerned with dealing with and helping reduce rising energy costs but also with the costs of discharging exhausts.

"With energy representing more than 60% of the total costs of a thermal system over a period of 10 years, it represents a constantly increasing expenditure. Consideration has also to be given to the cost factor, for example, for discharging the cleaned/recycled exhaust air into the atmosphere." Mr Heinrichs explained.

In this respect, Monforts ‘stand alone' Energy Tower has been introduced for retrofitting to existing stenters or hot flues with restricted access above the units. Designed to be positioned alongside the  stenter or hot flue it features five integrated heat recovery modules. Capitalising on the high temperature of the exhaust air, fresh air passing through the heat recovery system is heated and allows savings of up to 30% in energy costs to be achieved.

stenter or hot flue it features five integrated heat recovery modules. Capitalising on the high temperature of the exhaust air, fresh air passing through the heat recovery system is heated and allows savings of up to 30% in energy costs to be achieved.

In the same vein, Monforts says its new improved soft coating solution provides significant energy savings with reduced drying times. It can also eliminate the need for a conventional wet-on-wet padder.

The new process uses trough and roller techniques and applies just the required amount of liquid/coating to the fabric via contact with the roller.

It has been designed to offer three options - to apply a liquid/coating to one side of the fabric; to apply a liquid to both sides of the fabric; or to apply a liquid to one side of the fabric and a different liquid to the other side.

Klaus Heinrichs says, focusing on increasing productivity and innovative processes has also provided additional customer benefits.

Endorsing Monforts commitment to providing the textile industry with the lowest energy consumption together with improved levels of efficiency and production, the company has introduced its hi-E Efficiency Lifecycle Management package of energy saving benefits.

In a bid to reduce energy costs, Monforts has introduced its hi-E package of benefits which includes: Monformatic Plus Control; Top-S padder roller; TwinAir airflow; CADstream nozzle system; Conticlean automatic fluff cleaning; fan motors with Eff1 classification; and its energy saving Lift-O-Matic doors.

The Montex 8000 stenter from Monforts, which dominated the company's booth in Barcelona, includes a number of new features and options that are said to be particularly suited for knitted fabrics, nonwovens and technical textiles applications.

The new, European-built, Montex 8000 stenter features a new heat recovery module incorporating a fully automatic cleaning system for its integrated heat recovery system; a reduced distance at the infeed for knitted fabrics; a new heavy duty vertical chain; new rotating disc type ‘fluff-sieves' and a vacuum system for efficient cleaning; further improved visualisation for the company's Teleservice facility; and two parallel integrated exhaust ducts in each chamber.

The Montex 8000 on show, which was especially designed for ITMA, had a cut-away section which allowed visitors to walk underneath to view the internal workings of the stenter.

New heat recovery module

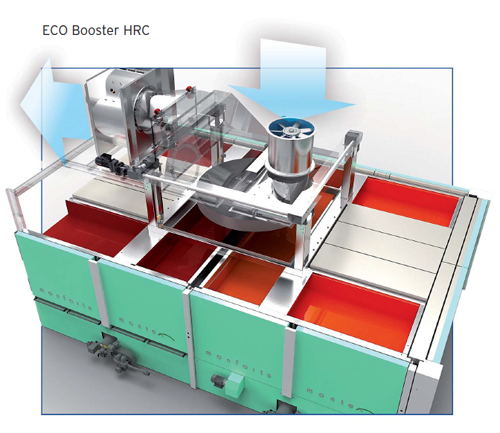

New heat recovery moduleA new heat recovery module ‘Eco booster HRC' with a fully automatic cleaning system has also been introduced, replacing the earlier modules' manually cleaned tubes system. Featuring a ‘honeycombed' design the new system cleans itself fully automatically during machine operation and ensures continuous uninterrupted high availability.

The system comprises a compact, air-to-air heat exchanger, which is installed within the roof structure of the stenter. The heat exchanger uses energy from the exhaust gas to preheat up to 60% of the incoming fresh air entering the stenter. Depending on production conditions, this is said to provide energy savings of 10-35% and a typical payback period of around just 12 months.

Featuring large diameter vertical tubes, the heat exchanger is said to require very little maintenance with extended service depending on production cycles and the fabrics being processed.

As part of Monforts ongoing effort to reduce energy consumption in the textile industry, its integrated heat recovery system is now fitted as standard on all new Montex stenters.

Reduced infeed distance for knitted fabrics

The new stenter is also available with a reduced infeed distance between the infeed roller and the needling point for knitted fabrics, preventing eventual edge curling. The distance has been further reduced by 60 mm.

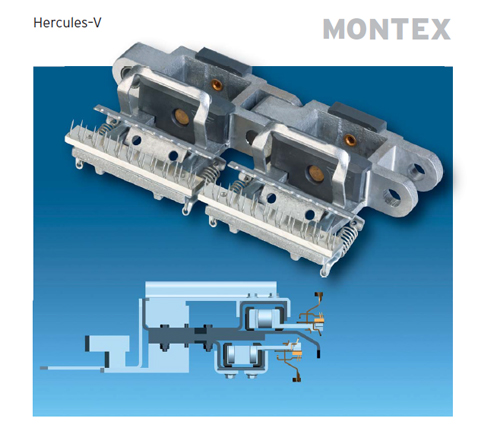

Heavy duty chain

Heavy duty chainComplementing the range of Monforts chains, and following a market request, the new stenter is also available with a heavy duty, ‘Hercules' type vertical chain; designed for heavier weight knitted, nonwoven and technical textile applications. The ‘Marathon' type vertical chain will be made available later together with the horizontal chain versions.

New rotating ‘disc type' sieves, each equipped with a vacuum cleaning system has been introduced as an option to collect fluff and ensure efficient cleaning and the highest machine availability. Two sieves per chamber can be fitted.

Designed for special coating processes and, technical and non-wovens applications, a new thermal splitting system allows different finishing temperatures in both the upper and lower nozzle systems.

According to Monforts this is ideal for applications such as automotive carpets where different temperatures are required on both sides of the product.

Used in conjunction with the stenters TwinAir system, the thermal split allows, for example, the drying air temperature of the top nozzles to be plus 30ºC higher than the lower nozzles.

Used in conjunction with the stenters TwinAir system, the thermal split allows, for example, the drying air temperature of the top nozzles to be plus 30ºC higher than the lower nozzles.

A new parallel, integrated, twin exhaust channel arrangement especially for technical textiles is also available for alternate chamber arrangements to offer a staggered ‘counter type' operation.

Further process visualisation on the new stenter offers improved Teleservice facilities with easier operation and screen viewing. New attractive flat-rates with no license fees are also available for Monforts Teleservice.

Also on show at Monforts was the latest Monfortex sanforizer. The Monfortex and Toptex compressive shrinking machines are well known and now Monforts a new generation of completely redesigned systems. They build on the experience of making Sanfor machines for the last few decades and integrate present customer requirements in terms of performance, technology and service.

Kalus Heinrichs points out the new features: "Typical features of the new Sanfor systems from Monforts include: improved residual shrinkage with lower rubber belt contact pressure; longer rubber blanket life and lower production cost; 40% less water consumption compared with conventional equipment; fully automatic grinding of the rubber blanket; and faster one-shift rubber blanket change."

Kalus Heinrichs points out the new features: "Typical features of the new Sanfor systems from Monforts include: improved residual shrinkage with lower rubber belt contact pressure; longer rubber blanket life and lower production cost; 40% less water consumption compared with conventional equipment; fully automatic grinding of the rubber blanket; and faster one-shift rubber blanket change."

The shrinking process takes place between the rubber belt and the heated shrinking cylinder. The pressure roll presses the rubber belt against the heated shrinking cylinder which is thereby stretched. When the pressure of the roll is relieved, the belt retracts again.

The fabric between the rubber belt and the cylinder has to follow this retraction of the belt and is thereby shrunk. Every change in the rubber belt pressure changes the fabric shrinkage. The higher the pressure, the greater the shrinkage.

Download the Monforts Innovations brochure here

For further information on Monforts products, please contact:

Klaus A.Heinrichs

A Monforts Textilmaschinen GmbH & Co KG

Blumenberger Str. 143-145

41061 Mönchengladbach

Germany

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more