UND and adidas partner on major apparel deal

Opinion

The PI Apparel World Series 2017-2018 brings together delegates from the apparel and footwear industry to showcase new and disruptive technologies.

3rd November 2017

Anne Prahl

|

Berlin

The PI (Product Innovation) Apparel World Series 2017-2018 brings together delegates from the global apparel and footwear industry to showcase and discuss new and disruptive technologies.

The Berlin event, which took place from the 26th to 27th of October, focused on digital product creation, effective data management and smart innovation and was attended by over 200 international delegates from more than 80 companies and academia.

Building trust in digital technologies

3D technologies for the apparel and footwear industry include systems for design and visualisation, material simulation, pattern making, virtual fitting, manufacture and sales, all of which are predicted to make the process more cost and time-effective, reduce waste and drive better and faster decisions. In addition, companies can become more consumer-centric, by utilising tools to provide the customer with better retail experiences and customised products. It is clear that digital tools and technologies provide exciting opportunities for the future, although adoption rates are currently still very low in the industry. As discussed by many presenters and delegates at the conference, the journey to successful technology adoption will be a slow and work-intensive one, while success depends on end-users being able to gradually build their trust in such systems.

In order to develop confidence and trust, collaboration is one of the most important factors; this includes external partnerships between end-user companies and software vendors, so that individual and brand-specific needs can be catered for, as well as internal teamwork between designers, pattern makers, fit and material technologists, product manufacturers and merchandising and sales teams. A good example is the collaboration between G-Star Raw and Gerber Technology, which pioneered the implementation of 3D technology for denim design. G-Star chose to start their digital technology journey in the pattern department, which allowed the company to train the pattern team and give them time to practice new skills, while simultaneously producing physical and virtual samples of each style. This enabled the team to increase confidence in the virtual samples, so that virtual fit approval and other 3D technologies can be introduced across all functions in the future.

Sportswear retailer Decathlon also shared their success story, in which the company teamed up with Assyst, who supplied both 2D and 3D software to provide an integrated system suitable for all relevant job functions. For Decathlon, this pilot resulted in teams communicating more efficiently, while fostering stronger bonds between the different departments. Additional advantages include the reduction of the number of physical samples, the elimination of samples in all colourways, the opportunity to replace expensive photoshoots with ‘virtual product shots’, as well as being able to make better decisions throughout the process.

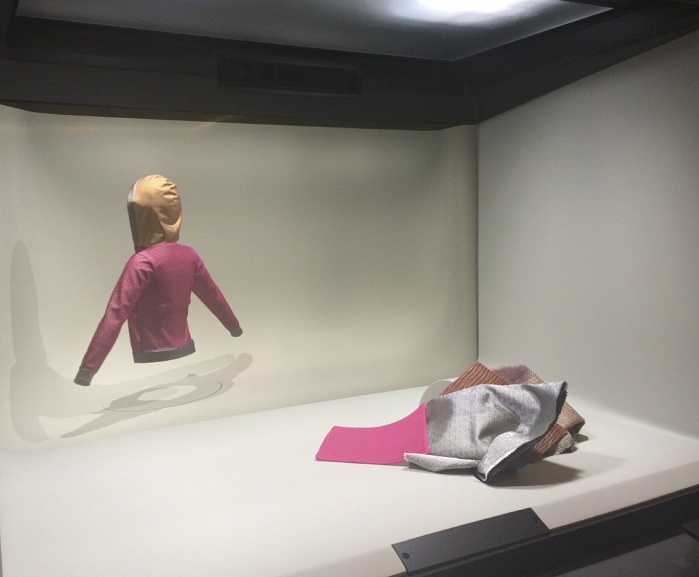

Swedish fashion studio Atacac provided inspiring insights into their collaborative approach, which sees founders Rickard Lindqvist, a fashion designer and researcher specialising in pattern cutting, and Jimmy Herdberg, a digital programming veteran, combining their different skill-sets to present a new business model. Utilising CLO Virtual Fashion’s 3D garment simulation software to design their collections, products are digitally designed and visualised, before they are sold on their website and are only produced once online sales indicate the demand for a product.

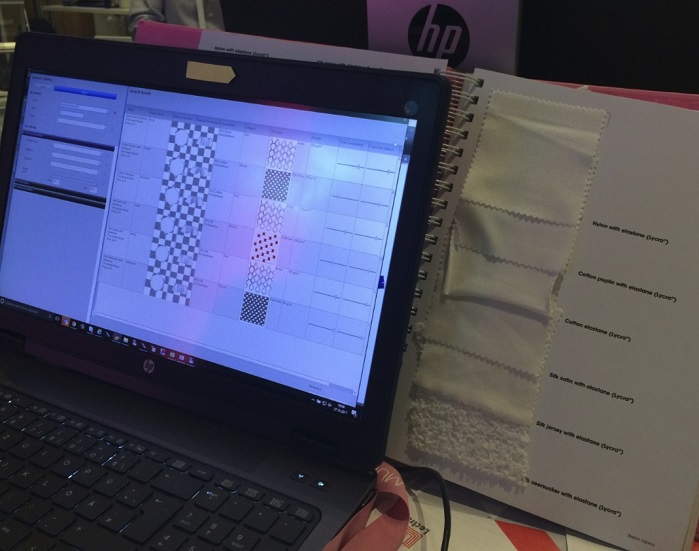

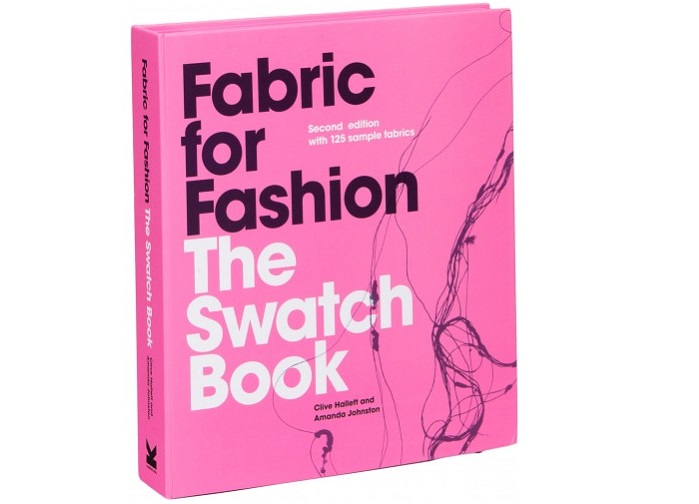

Digital innovations such as Atacac’s provide us with a glimpse of what is possible, however, while the industry is still at the beginning of its digital technology journey, it is also useful to consider the combination of tried and tested, with emerging methods. A great example was shown at Lectra’s demonstration booth; this combined the use of their integrated digital design software Kaledo with a ‘real’ swatch book to bring virtual textile simulations to life.

Key challenges for successful implementation

Due to the diverse user needs and required functions, designers, pattern makers, developers and manufacturing and sales teams often work with different systems and platforms and therefore compatibility is essential.

However, many of the speakers and delegates blamed the slow progress in 3D systems adoption on incompatibilities between the various software systems they need to work with. Issues around systems interoperability were also the key talking point during the panel discussion involving eight of the software vendors, hosted by Alexis Kantor of Target.

The panel debated passionately on how these issues of systems interoperability could be overcome but opinion was split on the end-user demand for standardisation. Although the group discussed the need for software vendors’ willingness to collaborate and develop or adhere to standards, this was also seen as potential threat to innovation. Asaf Landau from EFI Optitex pointed out that it is the nature of innovation to be new and different and therefore interoperability is unlikely.

He therefore suggested that software vendors should continue to push innovation in response to the complex user needs, while other groups should keep vendors on track in terms of interoperability. Delegates expressed their view that software vendors are making technology adoption very difficult, especially for smaller brands, and therefore support the call for third party involvement to achieve standardisation and interoperability. Going forward, this is one of the issues that could be taken on by the 3D Retail Coalition (3D.RC), a collaborative group of brands and retailers supporting the successful development and adoption of 3D virtualisation and visualisation in the global apparel, accessory and footwear industry.

Future opportunities

The use of 3D technology as a sustainability enabler was a common conversation point; while various talks referenced opportunities for waste reduction through the elimination of physical samples, fashion designer Martine Jarlgaard is looking specifically to blockchain technology to inspire a more sustainable approach. Her recent collaboration with Provenance, a consumer-facing blockchain-enabled platform, focused on highlighting the technology’s potential to create more trust and transparency in the fashion supply chain, as garments are registered and tracked via the Provenance app, from raw material, via manufacture to the finished garment in Martine’s studio.

Other glimpses of future use-cases for 3D technologies were provided by companies including Target and Columbia Sportswear, who are pioneering the use of Augmented (AR) and Virtual Reality (VR) for activities including design and construction, sampling, product development, merchandising, in-store experiences and product customisation.

Another exciting development is X-Rite’s Total Appearance Capturing (TAC™) Ecosystem, which combines a TAC7 scanner, PANTORA™ Material Hub desktop application and Virtual Light Booth to provide new levels of material accuracy and virtual product display, which may reduce the need for physical samples altogether.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more